GENERAL DESCRIPTION :-

- Heating Chamber :- Heating element made of kanthal resistance wire in coil form duly embedded.

- Insulation :- Glasswool & Mineral Wool. Insulation for max. thermal efficiency.

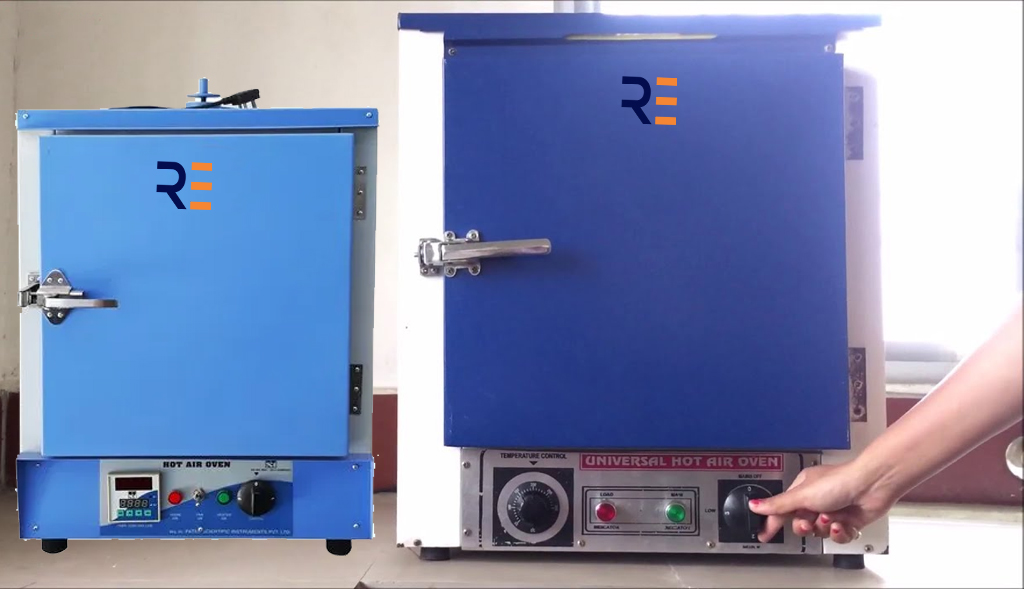

- Door:- Glasswool & Mineral Wool Insulated with Brass handle duly Nickled & heavy duty Alum. Casted Hinges. opens outward.

- Control :- The temperature of Oven is controlled by PID temperature Controller Cum-Indicator with SSR/ Relay.

- Ventilation :- Provided on both side of Oven.

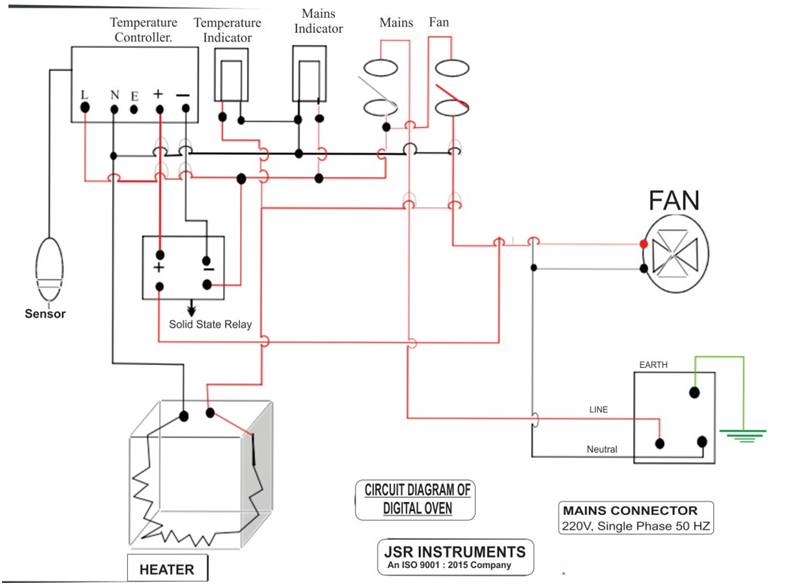

CONTROL PANEL:

- PID Temperature Controller Cum Indicator.

- Temperature Indicator, Mains Indicator.

- Mains Switch

CONSTRUCTION : –

The body of the Oven is fabricated out of MS Sheet 20 Gauge duly Powder Coated. Inner Chamber made of S. Steel orAlum. as per requirement

INSTALLATION :

- Connect the Oven to 220 /230AC Supply. Single Phase 50 HZ.

- Red Indicator will begin to glow.

- For Temperature Setting , Please go through attached manual.

- Green Indicator i.e. temperature indicator will begin to glow Indicating load on.

- Switch on the air Circulation system for better uniformity.

- The Oven will now start heating & load Indicator will glow & after some time the unit will start taking cut off & shall maintain the temperature at required position, Indicator will glow on/off when temperature reached below the set Temperature.

- Temperature of 100°C is achieved within 30 minutes, & higher range i.e. 200°C is achieved within 45-60 minutes or soon depending upon the wattage / Load & Size of the Chamber

TECHNICAL DETAIL :-

- 1.Maximum Temp. : – 250°C

- Continuous Temp. Working °C

- Temperature Sensor Fe/K-Type Thermocouple/Pt 100 4.Maximum Load 1.0 K.W to 4.5 K.W.(As Per Size)

INSIDE CHAMBER SIZE /CAPACITY /WATTAGE :

12” X 12” X 12”/28 Liters./1.0 KW. 14” X 14” X 14” / 45 Liters/1.0 KW.

18” X 18” X18”/ 95 Liters./1.5 KW. 18” X 18” X 24” / 125 Liters/2.0 KW.

24” X 24” X 24”/224 Liters./2.5 KW. 24” X 24” X 36” / 336 Liters/3.0 KW.

24” x 18” x 36” /252 Liters/2.5 KW.

FAULT FINDING:

No Power from Mains, No Indicator glowing on the Control Panel : –

Check the connection wire/ Load wire from the connecter – Terminal fitted at the bottom of the Oven. May be BURNT& loose.

Temperature Failure:-

- Check the SSR /Relay of PID Temperature Controller fitted in the Panel

- Check the PID Controller & its Relay

- Check the ER i.e. Fine Temperature Controller